Tlhaloso ea Sehlahisoa

| Mohlala | GJW-X3300 | GJW-X2500 |

| Bophara ba Mesh | ≤3300 limilimithara | ≤2500mm |

| Wire bophara | 6mm-12mm | 6mm-12mm |

| Sebakeng sa terata | ≥50mm | ≥50mm |

| Welding electrode No. | 32 | 24 |

| Mofuta oa terata | ≥1000mm, terata e sehiloeng pele | ≥1000mm, terata e sehiloeng pele |

| Mofuta oa mohala oa mohala | Mohala o sehiloeng pele | Mohala o sehiloeng pele |

| Lebelo la welding | 45-75 lichapo / min. | 45-75 lichapo / min. |

| Welding transformer | 180KVAX16 | 180KVAX12 |

| Phoso ea diagonal | ± 5mm (letlapa la letloo la bolelele ba 2m) | ± 5mm (letlapa la letloo la bolelele ba 2m) |

| Lintho tse bonahalang | terata e boreleli kapa e nang le likhopo (e batang e kentsoeng) | terata e boreleli kapa e nang le likhopo (e batang e kentsoeng) |

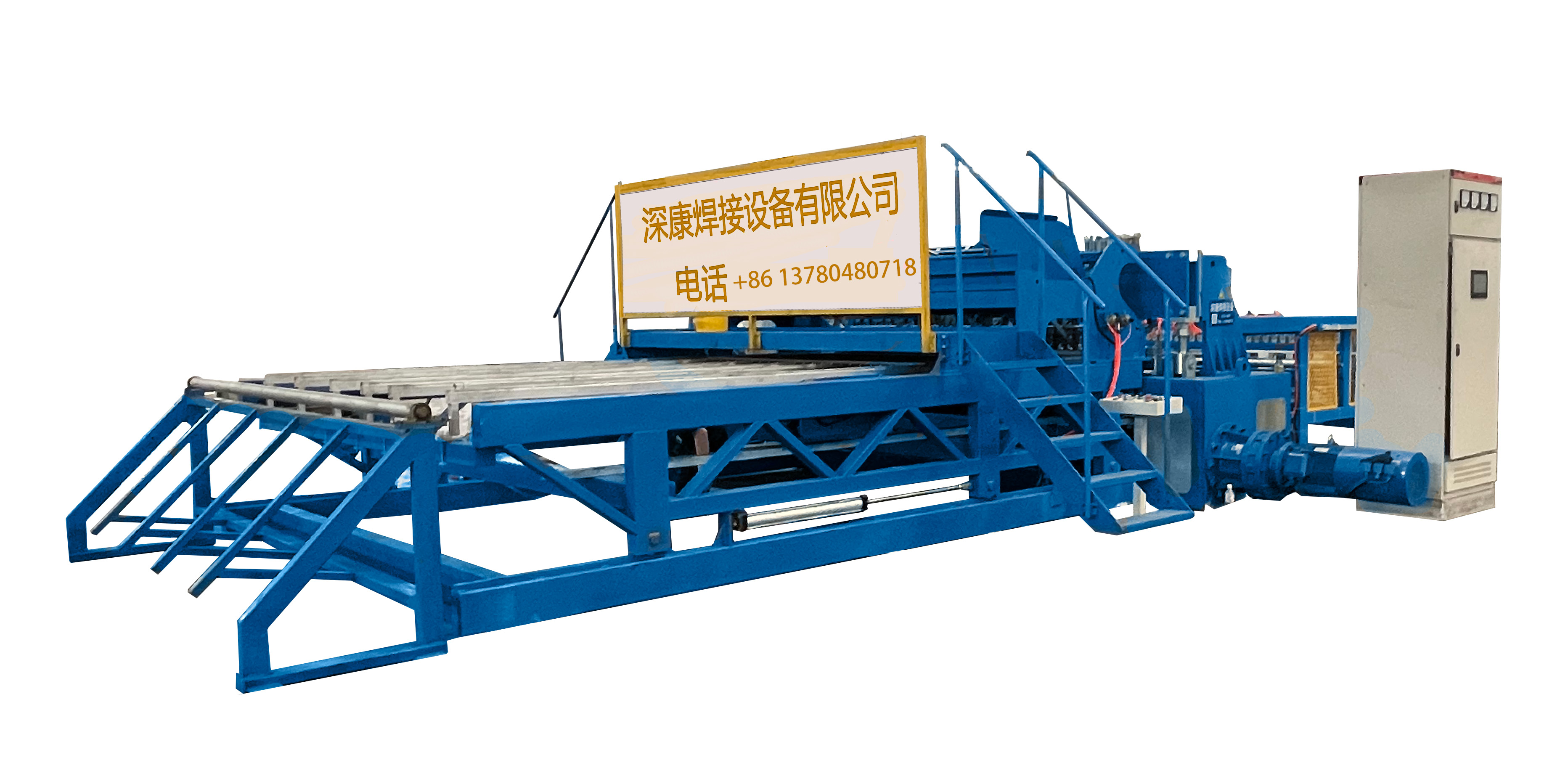

Mohala oa tlhahiso ea tšepe ea tšepe, bophara ba letlooeng le cheselitsoeng ke 3300mm, bophara ba terata ea welding ke 6-12mm, lebelo la ho tjheseletsa ke makhetlo a 45-70/min, le mela e otlolohileng le e otlolohileng kaofela e robehile.

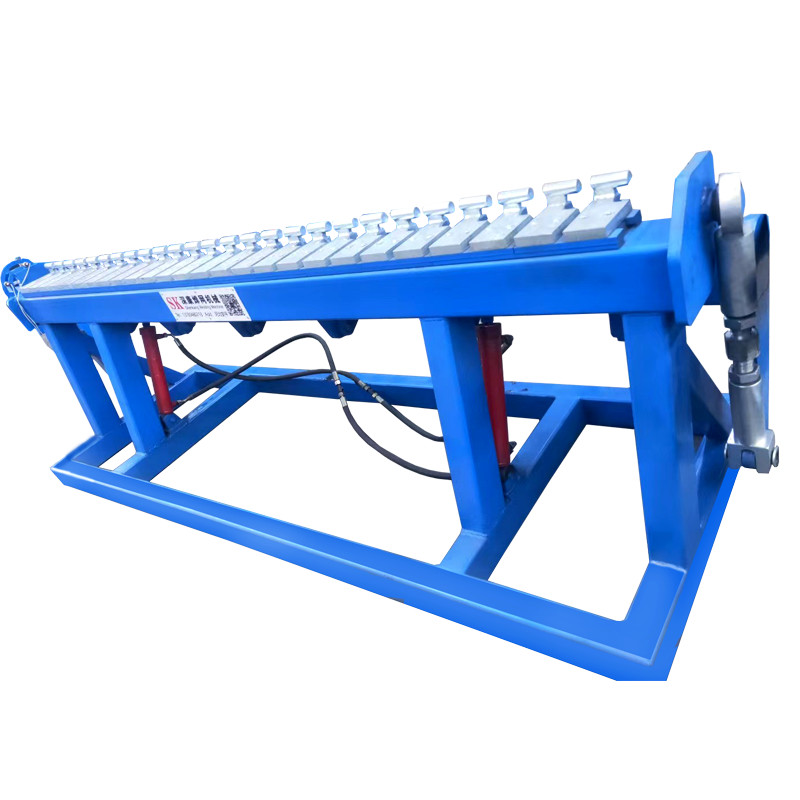

Tlhophiso e tloaelehileng: Rake ea ho fepa ea mela e telele, trolley ea ho fepa, moamoheli oa welding, ho eketsa sekoti sa thepa, letlooa le hulang servo.

Thepa ea boikhethelo: trolley ea ho theola le ho kenya marang-rang, ho fetola letlooa ka boiketsetso le nettincchiller;konpresser ea moea.

Kenyelletso ea Sehlahisoa

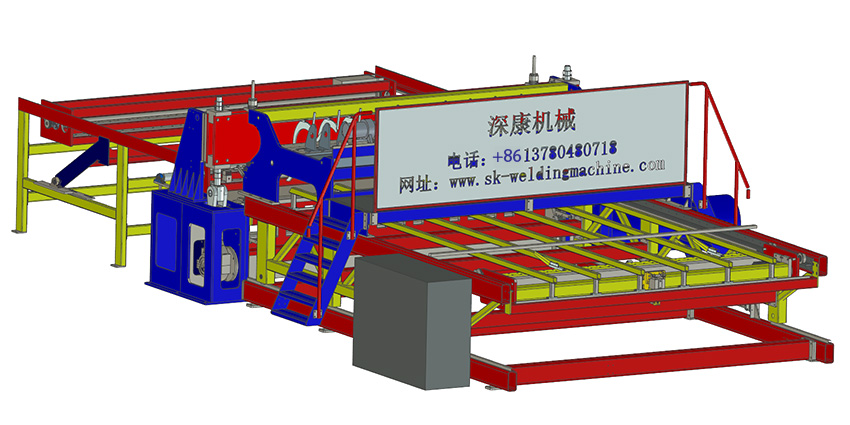

Mochini oa tšepe oa tšepe oa tšepe ke sesebelisoa sa othomathike sa ho tjheseletsa letlooeng la tšepe.Haholo-holo e entsoe ka sistimi ea welding, sistimi ea taolo le sistimi ea ho tsamaisa.

Sistimi ea welding e sebelisa mekhoa ea ho tjheseletsa ho hanyetsa ho kopanya rebar ho li-electrode ka li-electrode.Sistimi ea welding hangata e kenyelletsa toche kapa lithaole ho etsa hore eleketrode e kopane le rebar.Ka ho fana ka motlakase le ho sebelisa khatello, sistimi ea welding e khona ho ts'oara ka mokhoa o sireletsehileng eleketrode ho rebar.

Sistimi ea taolo ke boko ba mochini oa tjheseletsa, o ikarabellang bakeng sa ho laola litekanyetso tsa tjheseletsa, mokhoa oa ts'ebetso le lebelo, joalo-joalo Ka kakaretso, sistimi ea taolo e na le sekirini sa ho ama kapa sebopeho sa mochini oa motho e le hore opareitara a ka khona ho lokisa habonolo le ho beha leihlo ho cheselletsa. tshebetso.

Litsamaiso tsa li-conveyor li sebelisetsoa ho tsamaisa le ho beha li-rebar le lithupa tsa welding.Hangata e na le lebanta la conveyor kapa drum e tsamaisang li-rebar le li-welding rods ho tloha sebakeng sa ho fepa ho ea sebakeng sa welding le ho netefatsa hore li hlophisitsoe ka mokhoa o reriloeng esale pele.

Lisebelisoa tsa Sehlahisoa

Mochini oa tšepe oa tšepe oa tšepe o na le bokhoni bo sebetsang hantle, bo nepahetseng le bo tsitsitseng.E ka phethela ka bo eona mosebetsi oa ho tjheselletsa mesh ea tšepe, ea ntlafatsa ts'ebetso ea tlhahiso, le ho fokotsa litšenyehelo tsa basebetsi.Thepa e sebelisoa haholo kahong, marokho, lithanele le masimong a mang a tšepe ea tšepe.

Litlhahiso tsa Sehlahisoa

Hoa lokela ho hlokomeloa hore mefuta le mefuta e fapaneng ea mechini ea tšepe ea tšepe ea tšepe e ka ba le mesebetsi le litlhaloso tse fapaneng.Pele o reka, ho kgothaletswa hore o ithute ho eketsehileng ka litšobotsi tsa lisebelisoa tse fapaneng, 'me u khethe mohlala o nepahetseng le litlhaloso ho latela litlhoko tsa hau tsa sebele.